When transferring stocks using transaction MB1B, such as movement type 311 or 313, the SAP S/4HANA automatic batch copying feature conveniently copies the issuing batch information to the receiving batch automatically. However, this automatic batch processing does not occur when using transaction MIGO, which requires users to manually enter the receiving batch details.

This blog post explores the operational differences between MB1B and MIGO, the customization steps needed to address these inconsistencies, and user-specific solutions for enhancing SAP operational efficiency.

Table of Contents

What is Automatic Batch Copying?

Automatic batch copying refers to the process in SAP S/4HANA where the system automatically assigns the batch number of the issuing material to the receiving material during a stock transfer. This eliminates the need for users to manually enter the batch number for the receiving material, ensuring consistency and reducing the possibility of errors.

Imagine you are transferring 100 units of a chemical substance from storage location A to storage location B. The batch number for this substance at storage location A is “BATCH123.” If automatic batch copying is enabled, when you perform the transfer in SAP (using a transaction like MB1B or MIGO), the system will automatically assign “BATCH123” to the substance at storage location B, without requiring any manual input for the batch number.

Key Points:

- Batch Number: A batch number is a unique identifier assigned to a specific quantity of material that has been produced under the same conditions. It helps in tracking and managing inventory, especially for materials that require close monitoring, such as pharmaceuticals or food products.

- Issuing Batch: The batch number associated with the material that is being transferred from one location to another.

- Receiving Batch: The batch number that will be assigned to the material when it is received at the destination.

Understanding the Issue

To reproduce and understand the issue, follow these steps:

1. Customizing Path Configuration:

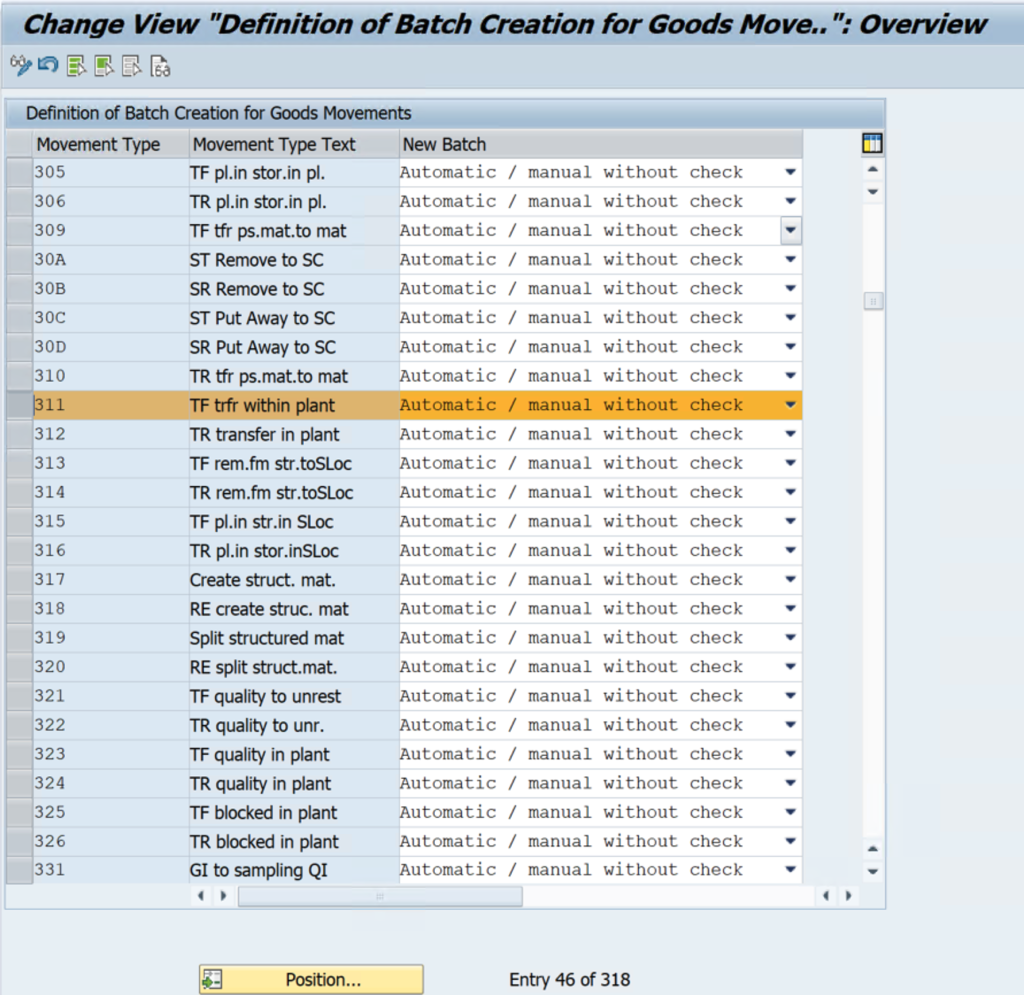

- Navigate through “IMG SPRO → Logistics General → Batch Management → Creation of New Batches → Define Batch Creation for Goods Movements“.

- For movement type 311, ensure that it is set to ‘Automatic / Manual without Check’.

2. Perform Stock Transfer Using MIGO:

- Go to the Transaction MIGO.

- Select “Transfer posting”, choose “Other”, and specify the Movement Type.

- Enter the Batch Number in the Issuing Storage Location and leave the Receiving Storage Location Batch Number blank.

- Select “Document OK” and press Enter.

- Observe that the Issuing Batch number is not copied over to the Receiving Batch Number.

The underlying reason is the deactivation of automatic batch number creation under the customizing settings for movement type 311. This discrepancy can cause inefficiencies and confusion among users accustomed to the more straightforward MB1B process.

This issue isn’t isolated to movement type 311; the same behavior can be observed in other movement types such as 301 and 309.

Configuring MIGO

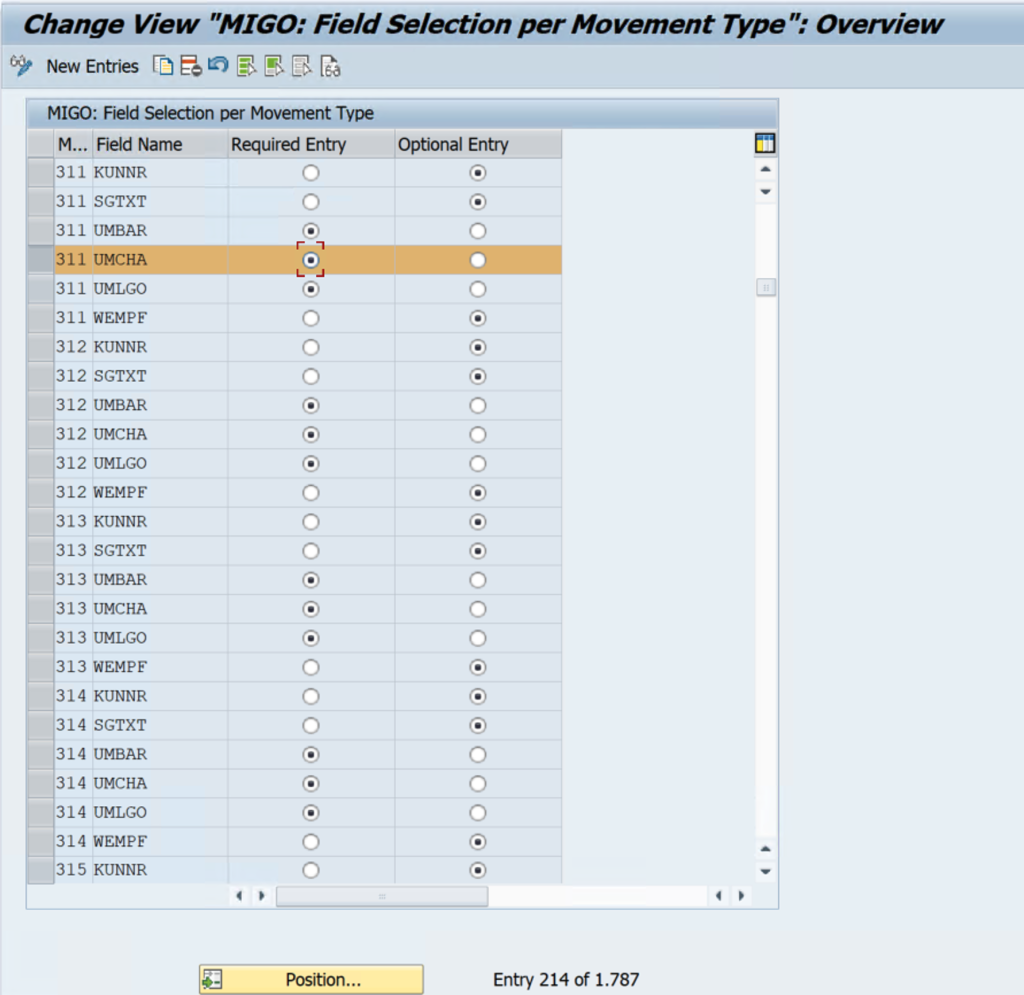

The inherent behavior of MIGO is dependent on custom settings. For movement type 311 in MIGO, the field UMCHA is set to “required,” necessitating manual entry by users. Understanding this customization helps devise a more tailored solution to streamline stock transfer processes.

To align MIGO’s behavior with MB1B, customizing settings within the system control needs adjustment. The customization of the field UMCHA (receiving batch) is crucial for movement type 311.

- Navigate to: SPRO -> Material Management -> Inventory Management and Physical Inventory -> Settings for Goods Movements (MIGO) -> Field Selection per Movement Type.

Here are the three configuration options for handling the UMCHA field:

1. Set as Required Entry: If the UMCHA field is marked as required, users must manually enter the receiving batch number.

2. Set as Optional Entry: if the UMCHA field is set to optional, the system will automatically copy the issuing batch number to the receiving batch field. Users can still manually overwrite this if needed.

3. Field Deletion from Customizing: If the UMCHA field entry is removed from customization, the issuing batch number will again be copied to the receiving batch field, but this time the field will be locked for modifications. Users won’t be able to alter the receiving batch number manually.

New Batch Creation in MIGO

If you wish to create new batch to be created in the Receiving Storage Location in Transfer Postings in MIGO, select one of the these options explained above. Refers to SAP Note#2544546 for more details.

- Set as Optional Entry

- Set as Required Entry.

Implementation of Custom Logic

If pre-defined system behaviors don’t align with operational requirements, custom logic can be implemented. SAP provides enhancement/user exits such as SAPLV01Z, EXIT_SAPLV01Z_001, and EXIT_SAPLV01Z_002 to tailor the batch management process.

Receiving Valuation Type (UMBAR)

The resolution methodologies discussed also apply to UMBAR, the field controlling receiving valuation type, leveraging similar customization.

Final Thoughts

In SAP, managing stock transfers effectively is crucial for maintaining streamlined inventory operations and consistent data accuracy. The discrepancy between MB1B and MIGO regarding automatic batch number copying can be mitigated with the right customization settings and enhancements.

By understanding and configuring the UMCHA field settings, aligning MIGO behaviors with the automated convenience of MB1B is achievable. Implementing these resolutions ensures that stock transfer processes are more intuitive, less prone to manual errors, and standardized across different transaction methods, ultimately driving operational efficiency and user satisfaction.

For more tailored solutions, leveraging user exits for advanced custom logic is a paramount strategy, providing the flexibility needed to optimize system performance specific to organizational needs